In competitive marketing, manufacturers of plastic crates need to provide crates with better quality at reasonable prices. Therefore, the highly interchangeable turnover box mold and the interchangeable version of the turnover box mold can produce different turnover boxes through one mold. It can help you meet the local market with less investment in Crate Mould manufacturing.

Because this interchangeable crate mold needs to be matched with different mold components to obtain the desired product. There are high requirements for the quality and size control of crate molds, so you should find a reliable manufacturer of interchangeable crate molds to avoid future costs. And you need to prepare basic knowledge about the essentials of replaceable crate molds.

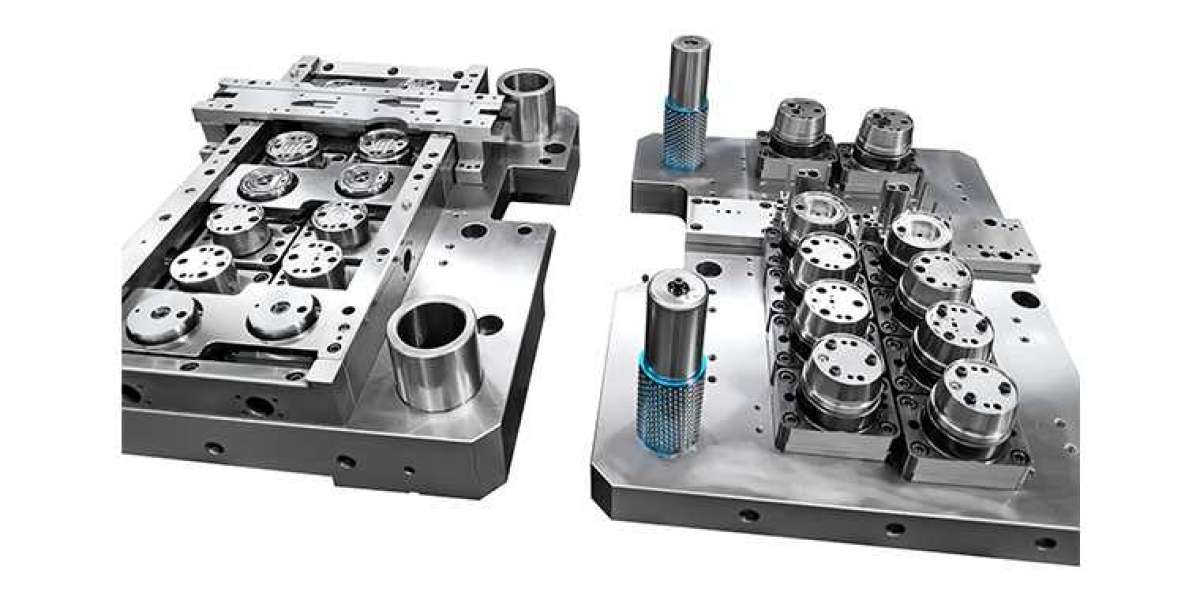

First, during the mold design process, we need to determine which mold components should be changed to obtain the target crate height or version. Through pre-analysis, the product parting line of these crates, as well as ejector slides, strippers or sliders, and ejector pods will be confirmed. Then select the mold technology, select high-precision CNC milling so that the dimensional tolerance of all main positions and parts (such as sliding seats, mold cavity inserts, wear plates, stripping grooves, etc.) is 0.05mm. Serious and experienced workers. Also, mark each mold part to avoid mixing problems.

Compared with standard plastic crate molds and Dustbin Mould, interchangeable crate molds are more complicated in processing and matching processes. The SHINE Mould team is committed to providing you with suitable solutions and achieving long-term stable operation.