basic introduction

Substrate material: L1, L2 ... LY ... LF ... etc.

Multi-layer material: T1, T2, T3 ... H96, H90, H85, H80, H70, H68, H65, H63, H62, H60, etc.

Production Process

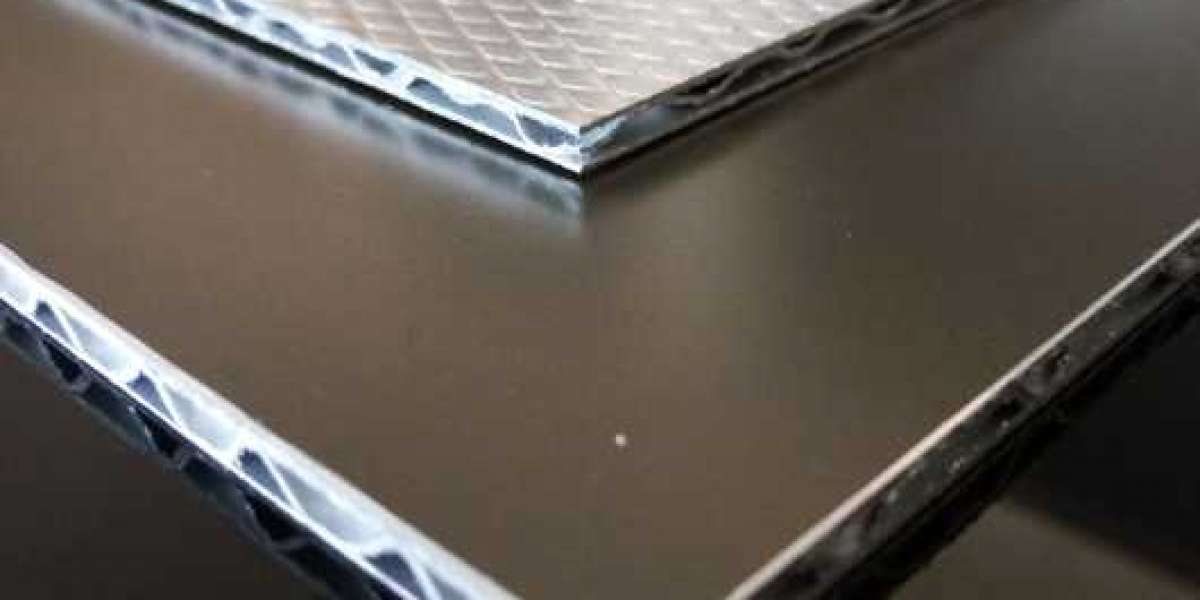

Hot rolling method: This method mainly rolls copper and aluminum composite thick plates

Cold rolling method: This method mainly rolls copper-aluminum composite sheet

Explosive compound method: This method is very fast and can be completed in an instant, with high bonding strength, and produces Aluminum Composite Panels.

Explosive rolling method: This method can produce copper-aluminum composite sheet. First, the rolled embryo is produced by the explosive composite method, and the sheet is rolled by rolling.

The mainstream technology of copper-aluminum composite plate is: explosive composite method, explosive rolling method.

Application area

Composite materials produced by the explosive composite method have been widely used in petroleum, chemical, shipbuilding, electronics, electric power, metallurgy, machinery, aerospace, atomic energy and other industrial fields.