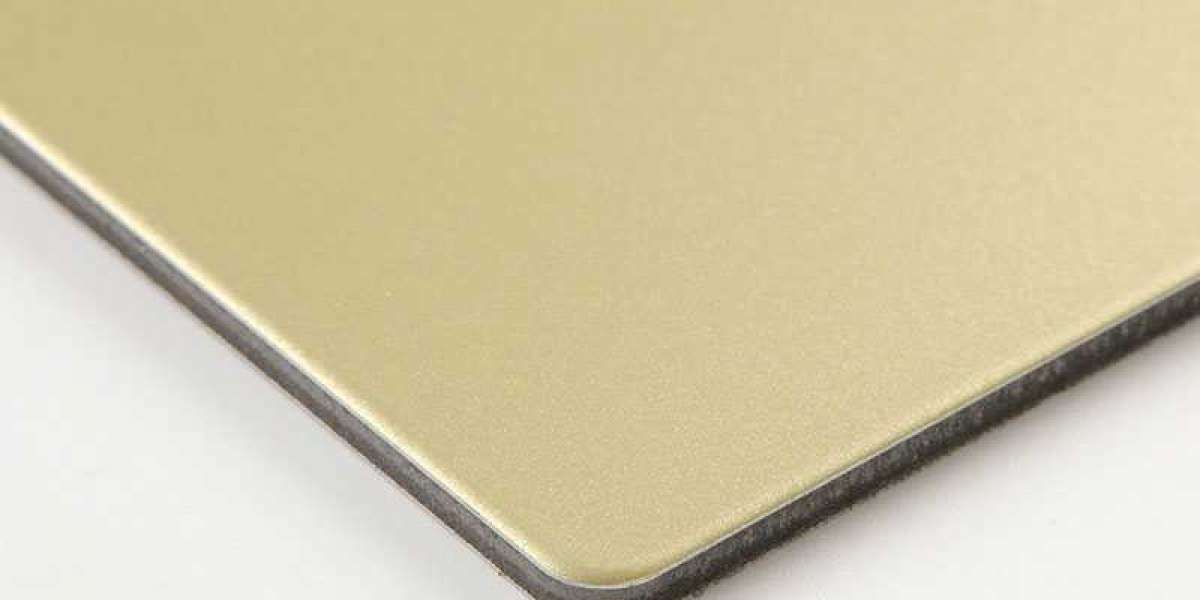

Metal Composite Panel refers to the metal layer on another metal panel. On the premise of saving resources, it does not reduce the use effect (resistance, mechanical strength, etc.) and reduces the cost effect. Composite materials usually include explosive compounds, explosive rolled composite materials, rolled composite materials, etc. Composite materials can be divided into composite panel, composite pipes, composite rods, etc. It is mainly used in anticorrosion, pressure vessel manufacturing, construction, petrochemical, pharmaceutical, light industry, automobile and other industries.

Common metal composite panel include titanium steel composite panels, copper steel composite panels, titanium zinc composite panels, titanium nickel composite panels, nickel steel composite panels, copper aluminum composite panels, nickel copper composite panels, etc.

Metal composite technical components can give full play to their respective advantages and realize the optimal allocation of material resources. In each case, precious metal materials are saved, and a single metal that can meet the performance requirements is used for stainless steel-steel composite panels for pressure vessels. For example, the base layer and ordinary carbon steel (Q245R, Q345R, etc.) have good mechanical properties, and the coated stainless steel (304316L) has good corrosion resistance. Usually, it is welded together by explosion, only a few millimeters are needed, and the price is stainless steel, thus saving a lot of costs and hardly changing various mechanical properties of the base material. It can replace imports, fill the domestic gap, has a wide range of applications, has good economic and social benefits, and is easy to obtain the support and help of all parties. For example, the development of stainless steel composites has been a high-tech project supported by the National Development and Reform Commission and the Ministry of Science and Technology.

Due to the properties, low cost and wide application of metal composite materials, the development potential of traditional metal composite materials has been improved. The enforcement of the national environmental protection industrial policy has been strengthened. The application of rare metal composite materials in power supply for flue gas desulfurization equipment continues to grow. At the same time, investment in the chemical industry has greatly accelerated the degree of localization, which also provides a good development opportunity for the development of rare metal materials.

The support of national industrial policies, high-tech barriers and the need for industrial upgrading provide broad space for industrial development. On the premise of saving resources, the metal composite panel on the metal layer and another metal panel does not reduce the use effect (resistance, mechanical strength, etc.) and reduces the cost effect.

The Fire-resistant Aluminum Composite Panel is also one of our product, welcome to buy and purchase!